Virgin polyester fabric seems to be a preferred option for making bags since it is strong, elastic, resistant to dampness, and – most significantly – affordable. But there is a big disadvantage to all these added benefits that cannot be ignored. The ecology is severely harmed throughout the polyester production process. In addition to wasting a tremendous amount of energy, it causes effluent to become contaminated with micro-plastics, chemicals, or other hazardous substances. Petroleum, a non-renewable resource, serves as the primary ingredient in the plastic fibers. That makes it non-sustainable Nevertheless, there is no denying that polyester makes excellent fabric. There is an environmentally friendly substitute that offers all the benefits of pure polyester. Recycled polyester is the name of this material.

RPET: What Is It?

Polyethylene terephthalate (PET), a form of plastic, is recycled to create recycled polyester (RPET), which is a fabric. Dimethyl terephthalate and ethylene glycol, both of which are sourced from petroleum, are combined to create PET. Despite being constructed from the same substance as virgin polyester fibers, the recycled fabric gets its PET primarily from used plastic bottles.

How Is RPET Produced?

The first step in creating RPET is gathering PET sources, in this case, plastic bottles.

Step 1: PET bottles are gathered and disinfected.

Step 2: The bottles are crushed into tiny, chip-sized pieces after being dried out.

Step 3: To create long strands of yarn, the heated PET bits are fed through a spinneret.

Step 4: Involves winding the PET yarn onto spools and running it through a crimping machine. The process of crimping is what gives the yarn its fluffy appearance.

Step 5: The PET yarn can then be bundled, colored the proper shade, and made into a cloth.

Virgin Polyester vs. RPET

Is there really a difference between virgin polyester and recycled polyester? To identify the key differences between the two fabrics, let’s analyze the components, sustainability, and their prices.

Materials

To begin with, virgin polyester is created only from PET, not from already-existing plastic items like bottles. As opposed to being gathered from abandoned waste, it demands that the PET be produced first. However, there is no distinction between virgin polyester and recycled polyester in terms of the final product. They both consist of woven PET cloth, which is effectively the same thing.

Sustainability

Recycled polyester differs from virgin polyester in another respect: it is more sustainably produced, from raw materials to finished goods. Compared to creating PET from scratch, recycling the PET bottles from polyester uses much less water and energy. In reality, RPET production requires 33% to 53% less steps than virgin polyester production. RPET can also be recycled repeatedly to create new products. As a result, we wouldn’t need to manufacture any additional virgin polyester. When a piece of recycled polyester is no longer needed, like an old bag or garment you no longer want, we may simply keep recycling it.

The mechanics of gathering, dispersing and purchasing for RPET present the biggest barrier to this reality. It’s a significant project that will necessitate a complete overhaul of the infrastructure at fashion companies. Even though RPET does have a carbon footprint, it is substantially less than what virgin polyester contributes to the environment. And if businesses ever manage to start deploying the technology to maintain recycling RPET, it has the capability to be much more sustainable.

Cost

Aside from manufacturing methods and sustainability, the difference between these two materials is pricing. Because there isn’t as much demand as there is for polyester right now, RPET is more expensive. However, as more businesses place a higher priority on sustainability and start utilizing recycled materials, such as RPET, the cost of RPET is projected to eventually equal out with that of virgin polyester and become more reasonably priced.

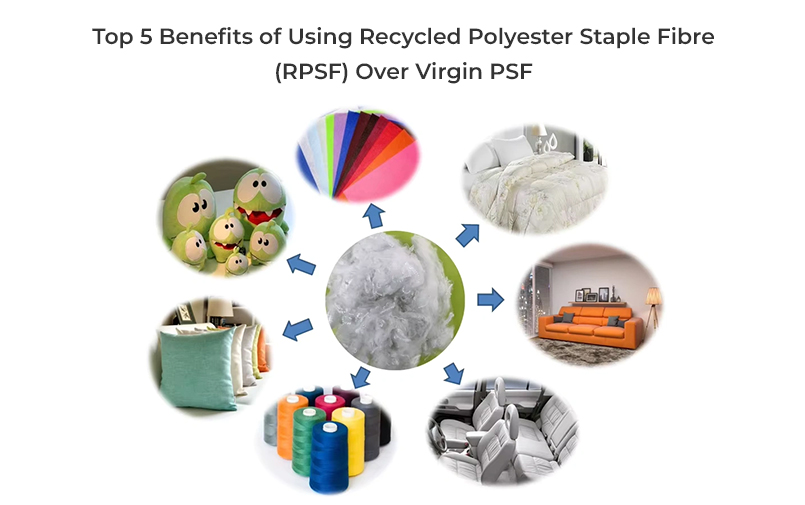

Recycled polyester’s benefits

The use of RPET has a lot of benefits. Given how much it resembles virgin polyester, it functions as if it were made from the same product in terms of the advantages it provides.

It is robust.

The robust and densely woven nature of recycled polyester fibers makes RPET a sturdy bag fabric. It can withstand a lot of pressure when you travel with it, use it for errands, transport textbooks or office materials, and perhaps even take it camping and trekking.

It prevents moisture.

A bag’s fabric must be resistant to moisture. RPET draws moisture from water and other fluids away similarly to virgin polyester. It also dries quickly after becoming wet because it doesn’t absorb fluids. This makes it the ideal option for handbags and backpacks you carry outside since there is always a chance you’ll get wet from a puddle or get rained on.

It is flexible.

Due to its elastic nature, recycled polyester maintains its structure well and won’t wrinkle or lose it even if it is pulled or bulges outward. A bag requires this property to be able to carry heavy objects and maintain its original shape while being worn around in a variety of situations.

It is resistant to heat.

Because recycled polyester has a high thermal resistance, it needs a lot of heat to ignite.

It retains colour.

Fashion businesses can utilise RPET to create accessories and clothing in a variety of brilliant colours because it retains colour effectively.

It has more sustainability.

Virgin polyester cannot be compare to recycled polyester in terms of sustainability. Petroleum-derived materials are used to make virgin polyester. Our air, water, and land are severely contaminated by petroleum refineries. While producing wastewater that is toxic and untreated, the companies that synthesis PET and make polyester are known to squander a lot of energy.

When a consumer no longer requires or desires a PET product, the object is discarded into a landfill, where it will slowly disintegrate over many years, releasing poisons into the soil. The virgin polyester life cycle is dismal. But one approach to make future world seem a little more promising is to recycle PET bottles into Recycled pet fabric.

JB Ecotex can ultimately reduce the requirement for virgin polyester entirely by using previously existing PET and converting it into a usable, polyester-like material using a less energy-intensive technique. In the meantime time, we can eliminate a production method that is harmful to the environment.